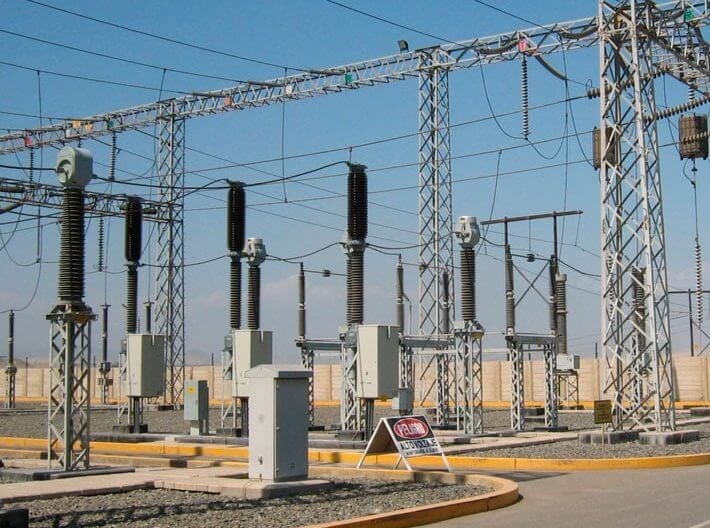

The reliability of any power distribution network relies on the right selection and integration of substation components. These complex systems bring together multiple disciplines of engineering where every component must work together seamlessly under all conditions. Component selection, specification and integration has become more critical as power systems adapt to renewable energy, smart grid and increasing demand for operational flexibility.

Modern substation components have come a long way from their predecessors with advanced materials, digital technology and innovative design that improves performance and reliability. The complexity of today’s power infrastructure demands understanding how individual components interact in the bigger picture, as engineers are under pressure to optimize both capital expenditure and long term operational costs.

The integration challenges of modern substation design requires careful consideration of component compatibility, protection coordination and future expansion. Each piece of substation equipment must be evaluated not only for its individual performance but also for its contribution to overall system reliability and operational efficiency.

Primary Power Equipment Systems

Power Transformers and Voltage Regulation

Transformers in electrical substations are the key to voltage transformation in power distribution networks. Transformers ensure that reliable voltage conversion. They do so while dealing with mechanical and thermal stresses associated with fault conditions. The selection of appropriate transformer technology depends on numerous factors. These include voltage levels, load characteristics, environmental conditions, and anticipated system growth.

Oil-filled transformers have remained the mainstay of high-voltage applications. This is because of their reliability and cost-effectiveness. However, dry-type units have been making inroads where fire safety and environmental issues take precedence. Transformer design has evolved to include high performance insulation systems, enhanced cooling technologies and sophisticated monitoring capabilities. This allows unprecedented access to equipment condition.

There is a need to consider the integration of substation transformers with protection systems, especially the differential protection schemes as well as gas-actuated relay systems. Transformer protection coordination with upstream/downstream devices requires careful analysis of the contribution of fault currents and clearing time to achieve selectivity in all the expected fault conditions.

Load tap changers are a vital part of contemporary transformer plants, which necessarily have automatic voltage regulation functions that ensure their ability to stay in service without compromising their service quality due to fluctuations in the supply voltage and changing load conditions. These mechanical devices require regular maintenance and careful coordination with voltage regulation schemes to ensure optimal performance throughout their service life.

Circuit Breaking and Switching Technology

From a system protection view, high-voltage circuit breakers are perhaps the most important substation equipment. These switches will be required to interrupt fault current with the capability of more than 50,000 amperes and still be capable of thousands of normal switching operations during their working life. The selection of one technology of interrupting over another (SF6 gas, vacuum, or air blast) is determined by both voltage requirements and environmental and maintenance considerations.

The introduction of circuit breakers in conjunction with digital protection relays has revolutionized the substation protection schemes and it has allowed complex fault detection logic as well as communication-based protection capabilities. Most modern installations use redundant protection schemes so that there is overlap of protection areas such that protection can be maintained in the case of equipment malfunction or maintenance.

The switching complement is aided by disconnect switches and grounding switches that are used to give visible isolation points and safety grounding opportunities that are necessary during maintenance activities. This mechanical design of these devices should be able to cater to large forces involved in switching actions and also offer reliable operation over a broad scope of environmental conditions.

Operating high voltage switching devices has been largely replaced by motor-operation, enhancing both safety and flexibility of operation, and allowing remote control. Mechanization of these systems with substation control systems needs the critical consideration of control circuit design and communication protocols.

Protection and Control Infrastructure

Digital Protection Systems

The modern protection systems present a radical shift in the traditional electromechanical relays to which microprocessor-based devices are included with the capability of performing more than one protection function in a single unit. These digital relays offer greater sensitivity, better coordination abilities and an ability to record all events fully to aid in not only in real time work but also in analysis after an event.

IEC 61850 communication standards have transformed the substation automation process and allowed standard communication between protection devices, control systems and external networks. This standardization of the protocol facilitates more advanced schemes of protection such as differential protection on multiple substations and adaptive protection which adapts settings to suit a system condition.

The substation safety equipment has advanced to include sophisticated arc flash detection systems where protective actions can be triggered within milliseconds, and hence the amount of energy released in the occurrence of arc faults is drastically decreased. Such systems are usually incorporated with traditional protection systems to offer a complete coverage of both conventional faults and arc flash hazards.

The system interaction of the protection systems needs advanced analysis systems and attention to be given to system impedances, fault current contributions and clearing times. Protection schemes should be selective, in all foreseen operating conditions and the engineers should ensure that there is sufficient backup protection to cover equipment failures.

Supervisory Control and Data Acquisition

SCADA systems have become integral to modern substation operations, providing operators with real-time visibility into system conditions while enabling remote control capabilities that enhance both safety and operational efficiency. The integration of SCADA with protection systems creates a comprehensive monitoring and control environment that supports both normal operations and emergency response procedures.

Human-machine interfaces within substation control houses must present complex information in an intuitive format that supports rapid decision-making during both normal and emergency conditions. The design of these interfaces requires careful consideration of operator workload, information hierarchy, and alarm management principles.

Communication systems supporting SCADA operations must provide reliable connectivity under all weather conditions while incorporating appropriate cybersecurity measures to protect against unauthorized access. The redundancy and diversity of communication paths often determine the overall reliability of remote monitoring and control capabilities.

Supporting Infrastructure Components

Grounding and Lightning Protection

Grounding systems within substations serve multiple critical functions, providing personnel safety, equipment protection, and system reference points that enable proper operation of protection and control systems. The design of substation grounding systems requires careful analysis of soil conditions, fault current magnitudes, and touch/step voltage limitations to ensure adequate protection under all conditions.

Lightning protection systems must address both direct strike protection and the more common induced surge protection requirements. The coordination between surge arresters, shield wires, and grounding systems requires sophisticated modeling to ensure adequate protection levels while minimizing equipment stress during normal switching operations.

The integration of grounding systems with metallic structures, cable systems, and electronic equipment requires careful attention to electromagnetic compatibility considerations. Modern substations often incorporate separate grounding networks for different voltage levels and equipment types to minimize interference and ensure reliable operation of sensitive electronic systems.

Auxiliary Power and DC Systems

Station service power systems provide the electrical energy required for substation auxiliary loads including protection systems, control equipment, lighting, and HVAC systems. The reliability of these auxiliary systems directly impacts the availability of primary substation functions, making redundancy and backup power capabilities essential design considerations.

Battery systems supporting DC control power must provide reliable energy storage while accommodating the varying discharge patterns associated with protection and control operations. The sizing of battery systems requires careful analysis of load profiles, backup time requirements, and environmental conditions that affect battery performance and life expectancy.

Battery chargers and DC distribution systems must maintain precise voltage regulation while accommodating the transient loads associated with circuit breaker operations and protection system activations. The integration of these systems with monitoring capabilities enables predictive maintenance approaches that optimize both reliability and cost-effectiveness.

Quality Assurance and Equipment Selection

Specification Development and Vendor Evaluation

The development of comprehensive equipment specifications requires deep understanding of both technical requirements and long-term operational considerations. Substation equipment suppliers must demonstrate not only technical compliance but also manufacturing quality, testing capabilities, and after-sales support that meets project requirements throughout the equipment lifecycle.

Factory acceptance testing has become increasingly sophisticated, incorporating digital simulation capabilities and standardized test procedures that verify equipment performance under a wide range of operating conditions. The coordination between factory testing and site commissioning ensures that equipment meets specification requirements while integrating properly with existing systems.

Equipment for substation applications must undergo rigorous type testing and routine testing to demonstrate compliance with applicable standards and specifications. The traceability of test results and quality documentation supports both initial commissioning and long-term maintenance programs.

Integration and Commissioning Challenges

Modern substation installations commissioning involves co-ordinated primary-equipment testing, protection-systems testing, control-circuit testing and communication-network testing. Such a systematic method makes all systems fully operational before energization and entry of services into them.

The commissioning of protection systems has been especially complicated with the advent of digital relays and communication based protection schemes. Not only engineers need to ensure correct relay settings but also the correct functioning of communication protocols and the interaction of several protection devices.

Incorporation of the new equipment with the available systems usually poses some compatibility issues that may necessitate some innovative ideas and rigorous testing processes. Legacy equipment might not have communication capabilities or protection systems that are included in modern installations and upgrade strategies must be considered carefully along with interim operating procedures.

Conclusion

The successful design and operation of electrical substations depends on the careful selection and integration of substation components that work together to deliver reliable, safe and efficient power. Each component – from massive power transformers to sophisticated digital relays – contributes to the overall performance of these critical installations that form the backbone of our electrical infrastructure.

Modern power systems require expertise that spans traditional electrical engineering principles and contemporary digital technologies. Substation components must be evaluated within the broader context of system requirements, operational constraints and future expansion plans to ensure long term performance and value.

As the industry continues to evolve with smart grid technologies, renewable energy integration and increasing demands for system reliability, the importance of expert component selection and system integration will only grow. The challenges of modern substation design require partners who combine technical expertise with practical experience in complex project execution.

IET has over 75 years of experience in substation components and system integration across East Africa. Our understanding of regional requirements, combined with our proven track record in power transmission and distribution solutions, MV switchgear and transformers, and intelligent control systems, makes us the go-to partner for complex substation projects. From design to commissioning and support, our team of experienced engineers deliver the technical excellence and execution you need for your critical infrastructure projects. Contact us today to discuss how our expertise can drive your project’s success.